A2PATS Delivery as a Discriminator

Textron Systems Electronic Systems’ Advanced Architecture Phase Amplitude and Time Simulator (A2PATSTM) is known and trusted as a high-fidelity electromagnetic environment simulator that generates complex simulations for numerous military and commercial applications. With decades of industry experience, Textron Systems Electronic Systems is optimizing its processes to meet customer needs today – and thinking ahead to future requirements. Senior Business Development Director Peter Johnson and Program Manager Pete Hughes explain how.

Q: What makes the A2PATS system unique?

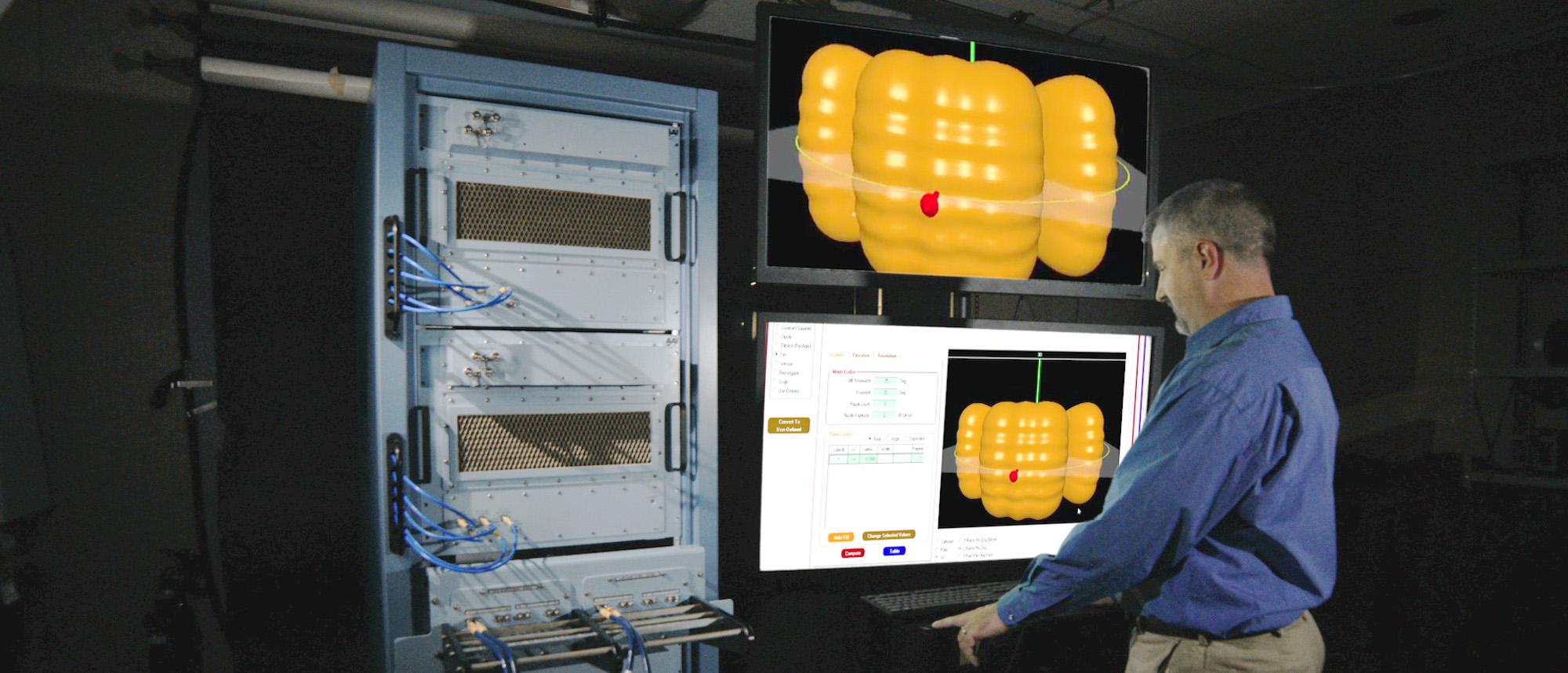

Johnson: Our customers include industry and academic institutions, as well as military labs. As a result, we have applied commercial best practices throughout our value chain. For example, from a design standpoint our system is modular, built with common components including standard cabinets and our standard radio frequency (RF) source, which we call Synthetic Stimulus Instruments, or SSIs.

Q: What does that mean for customers in terms of specifying an A2PATS system?

Hughes: We work with customers to make the process very simple, based on our SSI-driven direct-port architecture. Based on customer environment and use case, we determine the necessary port density and number of SSIs per port, which forms the baseline for the customer’s A2PATS system. We offer standard configurations from our Mini A2PATS to large, multi-cabinet configurations. The common design elements make it easy to scale customer solutions, and for customers to grow their capabilities over time as their needs evolve.

Q: How else have you applied commercial best practice to this product line?

Johnson: The very deliberate design approach we took for A2PATS has allowed us to manufacture these very complex, sophisticated systems in a commercial format. As a result, we can maintain suitable inventory levels of common components and subsystems to accelerate our time to delivery. While most of our customers adhere to similar buying timelines, there are certain cases for both domestic and international customers where fast-response deadlines arise. Our design and manufacturing approach enables us to meet those requirements.

For example, in late 2016 we were able to ship a standard-configuration A2PATS system for a major U.S. industry customer just two days after receiving the order. This customer had a unique set of time-sensitive requirements, and because of our design and manufacturing best practices as described, we were able to deliver on these requirements in record time. The system is up and running within the customer’s lab. The technology is complex, and takes time to manufacture. We were able to achieve this delivery due to the combination of standardized parts and available inventory.

Q: How does Electronic Systems support the customer past the point of sale?

Hughes: The A2PATS system is continuously aligned, so it does not require regular calibration services. That provides a great deal of additional value for customers in terms of availability and productivity. We offer spares provisioning and other maintenance services to keep systems in optimal condition. The A2PATS system sets a high benchmark for system performance and reliability over time.